Powder 101: Operating the Wagner Control Unit

Published by Jeremy Agosta on Jun 14, 2022

The EPG Control Box, used in the Wagner Sprint Trolley and Wagner Cup Gun, is a versatile tool that coaters can use to perfect their technique.

Dialing in the control unit for specific uses can take some time, but is well worth the effort. The control unit functions as the brain of the powder system, telling every other part what to do and how much to do it. Getting comfortable and confident with adjustments will pay dividends in production.

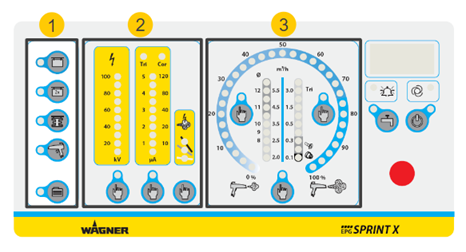

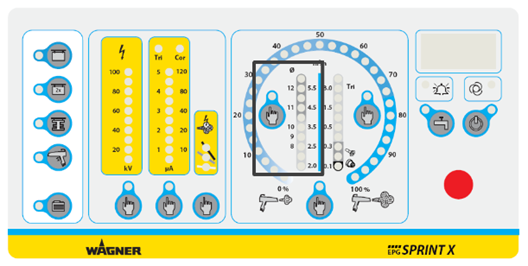

The control box has three major sections:

1. Recipe Management

2. Electrostatic settings

3. Air settings

Section 1 shows the presets loaded onto the unit.

From top to bottom, the preset recipes are:

- First coating of a flat part

- Second coat on a curved first layer

- Geometrically complex component

- Double click function

- Additional memory slots – up to 46

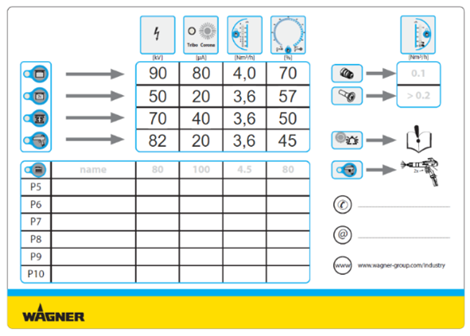

Perfecting settings and adding presets are great steps in configuring the unit to streamline coating as much as possible. However, overwriting the factory settings will delete the pre-loaded settings forever. The included sticker (attached below) can be used to recover these settings as well as function as a springboard for experimentation.

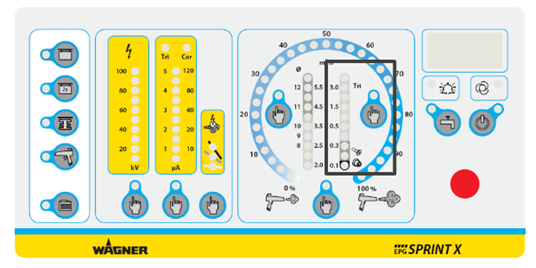

Section 2 controls electrostatic calibration.

The first trigger pull will cause the unit to automatically detect the type of gun being used. If the system detects a Tribo gun, section 2 will be deactivated.

The left most column allows for kV adjustment. The higher the kV, the more field lines – the lower the kV, the fewer field lines.

Wagner recommends starting with the kV setting at 40 kV or less.

The center column of section 2 controls and limits current (μA). This adjustment between high current and low current affects the width of the field. Higher current will make the field narrower while a lower current makes it wider.

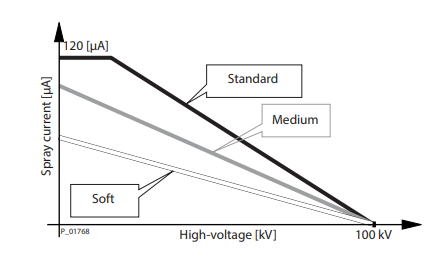

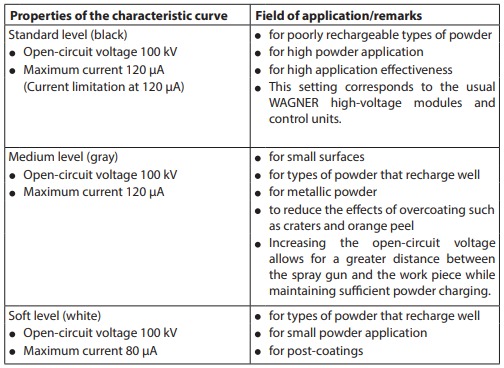

The third column in section 2 alters the characteristic curves.

Section 3 on the EPG Sprint controls the air settings.

Total air is highlighted below, it controls the speed of the air moving through the unit. At the correct speed the air should be constant and uniform. If the speed is too low, the powder cloud will pulsate and generate an unstable powder cloud. Even worse, if the speed is set too high the object being sprayed may suffer from blow-offs.

On the right side of the 3rd section is the atomizing air control. For a corona spray gun with a flat spray nozzle the setting should stay around 0.2 Nm³/h. For a round spray nozzle it should stay at approximately 0.5 Nm³/h.

This setting is vital in cooling any corona spray gun and should never be turned off.

For the Tribo, this number can vary depending on the powder.

Powder amount percentage shows the percentage of powder air being mixed with the total air moving through the system. The higher the percentage, the more powder. Typically, this setting will be between 30% and 75%. Lower than 30% may cause the cloud to pulsate. Higher than 75% may result in too little air to propel the powder.

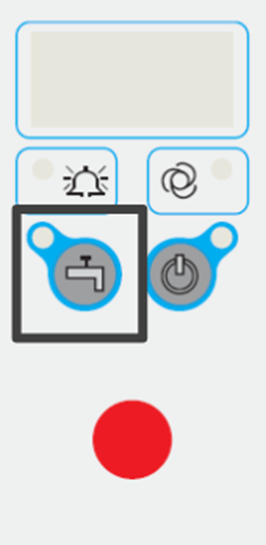

The flushing function is used to change the powder being sprayed. This function does a rough cleaning of the injector and powder hose. These parts should also be cleaned manually to prevent contamination of the new powder. Wagner recommends keeping the flushing function active until no outcoming powder is visible.

Questions about using the Wagner Control Unit? Contact us at sales@cetinc.com or (586) 210-0555

Find the lowest price on Wagner Powder parts at store.cetinc.com.