Description

Overview

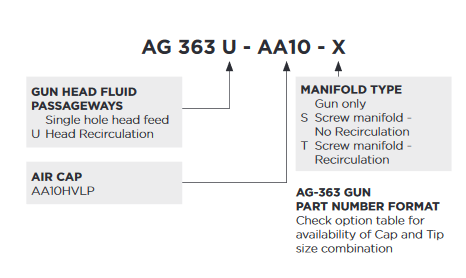

The Binks AG-363 combines the best features of Air Assisted Airless atomization and Binks engineering to provide a superior atomization and finish quality coupled with the highest possible transfer efficiencies, resulting in significant paint savings while complying with the toughest EPA regulations.

- Unique single screw attachment to manifold allows quick and easy removal for maintenance and cleaning, reducing downtime

- HVLP air cap technology produces excellent atomization with superior transfer efficiency and finishes

- Air cap has optional 15° indexing for fast and repeatable air cap and tip positioning

- Manual adjust air controls for easy spray fan adjustment and width control Stainless Steel gun head and fluid passageways for Water based and Solvent based coating compatibility

- Tungsten Carbide needle and seat for long working life and enhanced abrasion resistance Choice of paint re-circulation through gun head or manifold

Technical Specifications

- Gun Category: Air Assist Airless

- Gun Type: Air Assist Airless

- Fluid Passages: Stainless Steel

- Max. Pressure: 4000 PSI

- Weight: 840g

- Construction: Quickclean™ Coated Aluminum

| ||

| P1 = | Max Air Input Pressure | 10 Bar [145 psi] |

| P2 = | Max Fluid Input Pressure | 275 Bar [4000 psi] |

| P3 = | Cylinder Air Pressure | 4 - 10 Bar [58 psi - 145 psi] |

| ENVIRONMENTAL | |

| Max Ambient Operating Temperature | 40°C Nominal [104°F] |

| MATERIALS OF CONSTRUCTION | |

| Gun Head and Fluid Passageways | Stainless Steel |

| Gun Body Material | Quickclean™ Coated Aluminium |

| Air Cap Material | Anodised Aluminium |

| Fluid Needle and Seat Construction | Stainless Steel |

| Tungsten Carbide | |

| Seals and O-Rings | HDPE, FEPM |