The new units combine Wagner's industry proven manual coating technology with newly improved components and quality of life innovations to achieve the next level of quality and ease of use.

The Perfect Recipe

All relevant parameters for coating jobs are set via the WACON Sprint 2 Expert control unit with 7-inch touchscreen. The intuitive menu navigation also offers recipe management, error history, operating hours and maintenance counters as well as user management. The highlight of the control system is the WAGNER Wizard: With the intelligent coating assistant, even inexperienced users can find the right recipe for every coating job. In 5 simple steps, you select the workpiece geometry, size, coating structure, desired coating thickness and type of powder, and the Wizard uses these parameters to determine the ideal recipe. It also provides recommendations for suitable accessories (e.g. nozzle type, nozzle extension) and the required gun distance so you can get started straight away. With the DSO (Digital Surface Optimizer) assistance function - which is also integrated in the Sprint 2 - overcharge effects, such as orange peel or edge build-up, can be reduced at the touch of a button. This advantage is particularly relevant for decorative coatings on complex components or with demanding powder coatings.

New Injector Offers Numerous Advantages

Just like the Sprint 2, the Sprint 2 Expert also features the new Quick-Link injector. Optimized nozzle geometries reduce the air requirement and hose diameter needed, resulting in a significantly softer powder cloud at a lower speed. This results in a wide range of applications - from fine, decorative coatings on small parts to corrosion protection for large components. The injector also speeds up the cleaning and color change process: all powder and air hoses can be detached in one easy step using the Quick-Link coupling. The integrated scraper ring in the swivel arm scrapes the powder off the outside of the lance. For even faster color changes - in less than 30 seconds - a special cleaning set with automated internal cleaning of the suction lance is available as an option for the Sprint 2 Expert.

Process Documentation Made Easy

A powder scale under the base plate is used for precise monitoring of the powder consumption. This scale shows the weight in the powder box and automatically sets measuring points, which are documented in a logbook with the active user, selected recipe and coating period. This allows relevant coating data to be bundled and evaluated. The user can download all process data from the control unit via USB for further processing. Additional interfaces are available for the control unit to enable connection to higher-level systems, robot technology or a cloud solution - such as the COATIFY information and management platform

The Right Solution for Every Application

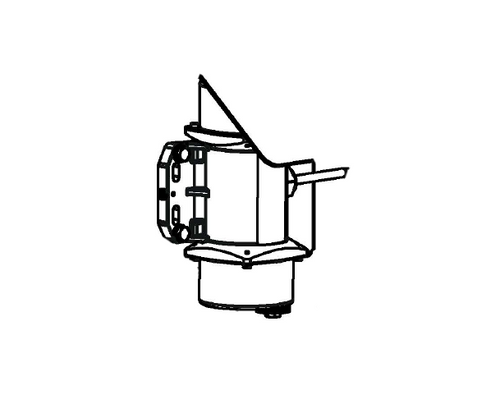

The multifunctional head module of the Sprint 2 Expert with the standardized perforated plate structure offers dust-protected storage areas and hanging options for tools and accessories. This keeps everything tidy and within easy reach. The manual system can also be quickly upgraded to a double system with two guns. The head module offers space for the installation of a second control unit.

Key reasons to upgrade:

- Air Flow Control for precise application

- Digital Surface Optimizer for complex workpieces

- Quick-link injector for fast color changes

- Efficient cleaning with swivel arm and wiper ring

- Versatile design for various container types

Additional advantages in Faraday areas:

- Reduces overcharging on complex parts

- Ensures uniform coverage in tight spaces

- Enhances coating on high-penetration surfaces

The Sprint 2 system utilizes the same dependable PEM-X1 spray gun and improves it with the new WACON Sprint 2 XE controller for optimum powder preparation, consistent results and exceptional quality.

- New venturi nozzle reduces powder velocity, improving the finish

- Quick-Link injector provides constant powder flow with optimized collector and updated nozzles

- Fixed suction lance improves fluidization and suction

- Updated hose management feature provides a cleaner and tidier workspace

- Additional wheels bring improved maneuverability and mobility

- Added whipper ring and redesigned swivel arm reduce cleaning time as well as allowing users to add a second powder coating system